Related entries: Extracts

Extracta Liquida, Br.; Fluid Extracts; Extraits liquides, Fr.; Extracta fluida, P. G.; Fluidextrakte, Flüssige Extrakt. G.

"Fluidextracts are concentrated liquid preparations of vegetable dings, containing alcohol either as a solvent or as a preservative, and bearing a uniform relation to the drug used so that one mil of the fluidextract closely represents the activity of one gramme of the air-dried and powdered drug of standard quality." U. S.

The Latin title Extractum—Fluidum formerly used for Fluid Extracts was dropped by the U. S. P. VIII because of the confusion which resulted from the necessary bringing together of the extracts and fluid extracts due to a strict alphabetical arrangement; the name "fluidextractum" is now used for "fluidextract" and the latter made one word; this, of course, brings the fluidextract under the letter F instead of the letter E under which extracts and fluidextracts were formerly both classed.

Fluidextracts were first introduced into the U. S. P. of 1850 as a distinct class of preparations, the fluidextract of sarsaparilla being the only one previously directed, either in our own official code or by the British Colleges. Now we have one hundred and fifty-seven that are official in the U. S. P. IX, British Pharm., 1914, and National Formulary IV, besides large quantities of non-official fluidextracts annually produced. They are now perhaps the most important class of liquid preparations in use. Their distinctive character is the concentration of the active ingredients of medicinal substances into a small bulk, in the liquid form, a cubic centimeter, mil, or fluidgramme of any one of them now representing a gramme of the crude drug. In addition to convenience of administration, the advantage of these preparations is that, evaporation not being carried so far as in ordinary extracts, the active principles are less liable to be injured by heat. Formerly their main difficulty was the liability of substances in the liquid state to undergo spontaneous decomposition. In the U. S. P. of 1850 this was counteracted by means of sugar and of alcohol, but in 1865 (A. J. P., 1865, p. 50) Taylor proposed the use of glycerin, which was adopted in the U. S. P., 1870, revision. Glycerin, while it exerts a powerful preservative influence, possesses the valuable property of dissolving matters deposited by some of the fluidextracts when made with sugar, as in the old official recipes. Consequently these fluid-extracts were much clearer and better preparations than were the old ones. Subsequent experience with these fluidextracts showed that the use of glycerin should be circumscribed, and that it had been employed too freely in the U. S. P., 1870, formulas. The solvent powers of glycerin are so great that the fluidextracts were frequently loaded with many inert principles, which it dissolved, giving them a dense, rich appearance, without increasing their activity. As the primary object of fluidextracts is concentration, suitable menstrua should in each case be selected with the single object of dissolving and retaining permanently the active constituents of the drug.

The present fluidextracts are of the same strength as those formerly official, and the formulas are based upon the theory that from a given weight of drug an amount of fluidextract shall be made equal in measure to the bulk of the same weight of distilled water; in other words, upon the relation of gramme to millilitre. Although the metric system is admirable in practice, some may prefer to use ordinary weights and measures; in such cases, to make 20 fluidounces of a fluidextract 19 troyounces of drug will be required, while if avoirdupois weight is preferred, the most convenient relation to recollect will be that 50 avoirdupois ounces are required to make 48 fluidounces, or three pints, of a fluidextract. It has been repeatedly proposed to make 50 per cent. tinctures or half-strength fluidextracts, the main object being to secure more representative preparations when made on the small scale. Experiments by Sayre, Gregory, Patch, and others prove that half-strength fluidextracts possess no advantages over those of official strength. (D. C., 1897, 119, 147.) The precipitation experienced heretofore, when the evaporated weak percolate was added to the reserved portion, is considerably diminished by causing the former to be evaporated to a soft extract. This precipitation, formerly noticed more particularly in alcoholic fluidextracts, was due to the greater volatility of the alcohol in the weak percolates, which, when evaporated, left the residue to a great extent aqueous; when this was added to the strongly alcoholic reserved portion, a precipitation of resinous and frequently active matter took place, which necessitated the storing of the fluidextract until precipitation ceased, and subsequent filtration. This is not altogether avoided by evaporating to a soft extract, but the loss of activity through precipitation is thus greatly diminished. Fluid-extracts invariably deposit insoluble matter upon standing, and those made in warm weather, owing to the greater solvent powers of the menstrua (due to the elevated temperature) are found to deposit more freely than the same kind of fluidextracts if made in the winter time with menstrua correspondingly reduced in temperature.

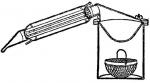

A useful distillatory apparatus has been contrived by Joseph P. Remington for recovering alcohol from weak percolates, and for general pharmaceutical uses. The still shown in the cut is the new form. It is made of tinned copper, the still body holding about three gallons; the condenser has seven straight tubes surrounded with the cold water introduced by a rubber tube from a hydrant or bucket of water placed higher than the still, and carried off as it becomes warmed by the tube shown at the upper part of the condenser.

By a siphon arrangement not shown in the cut, the still can be fed from a reservoir while distillation is in progress, thus using a three gallon still where otherwise a much larger one would have been necessary. The joints are carefully ground, and troublesome lutes and water joints are entirely superseded. The condenser, having straight tubes instead of a spiral one, is easily cleaned, and is powerful enough to condense a gallon of alcohol in thirty minutes. The still may be set into a kettle partly filled with water and thus used as a water bath, or a shallow tinned copper dish with flat rim, which accompanies the still, may be placed between the two brass ring bands and clamped securely. (A. J. P., May, 1879.) Remington's Practice of Pharmacy, Fourth ed., page 158.

By a siphon arrangement not shown in the cut, the still can be fed from a reservoir while distillation is in progress, thus using a three gallon still where otherwise a much larger one would have been necessary. The joints are carefully ground, and troublesome lutes and water joints are entirely superseded. The condenser, having straight tubes instead of a spiral one, is easily cleaned, and is powerful enough to condense a gallon of alcohol in thirty minutes. The still may be set into a kettle partly filled with water and thus used as a water bath, or a shallow tinned copper dish with flat rim, which accompanies the still, may be placed between the two brass ring bands and clamped securely. (A. J. P., May, 1879.) Remington's Practice of Pharmacy, Fourth ed., page 158.

For valuable papers on percolation and fluid-extracts, by William Procter, E. R. Squibb, Alonzo Robbins, and others, see Proc. A. Ph. A., 1859, p. 265; 1863, p. 222; A. J. P., 1878, pp. 209, 329; 1873, pp. 85, 189.

Several methods have been suggested for preparing fluidextracts more economically. The use of acetic acid as a menstruum to replace alcohol or diluted alcohol has the merit of economy. (See Extracta, also A. J. P., 1899, 1-14; Proc. Pennsylvania Pharm. Assoc., 1898, 116; A. J. P., 1898, 543; A. J. P., 1899, 67; Ph. Era, 1898, 796; Proc. Minnesota Pharm. Assoc., 1902, 103; West. Drug., 1903, 652.)

The most important modification is the plan of repercolation, as proposed by E. R. Squibb, for this class of preparations as well as the dry extracts.

Repercolation.—In consequence of the existing high price of alcohol, it is important to adopt some plan by which, while the ends aimed at are attained, the consumption of the menstruum used in percolation may be diminished. This object has been accomplished, to a considerable extent, by E. B. Squibb, of Brooklyn, N. Y., by a modification of the process of percolation to which he has given the name at the head of the present paragraph. As defined by the author, repercolation consists in the successive application of the same percolating menstruum to fresh portions of the substances to be percolated. The result is that the same menstruum, acting repeatedly on unexhausted portions of the substance, becomes concentrated to the greatest possible extent, so that much of the menstruum is saved, while subsequent evaporation is avoided, which is itself an object of great importance in the preparation of extracts. It is obvious that repercolation is not applicable to the preparation of infusions, decoctions, tinctures, etc., in which the object in general is less a high degree of concentration than precision in the strength of the preparation, and consequently in the dose. It is to the extracts and fluidextracts that the process is peculiarly adapted, and there now remains no doubt whatever of the great value of the improvement. One of its disadvantages is that the substance treated is less completely exhausted than when the proceeding is inverted, and fresh portions of menstruum are made to act on the same material until the latter is deprived of all its soluble matter. But the loss in this way is trifling, compared with the gain when a menstruum as high-priced as alcohol is employed.

Another practical disadvantage is the inconvenience of keeping the weak percolates, as these have to be labelled, numbered, and stored away for use until the same operation is repeated. In deciding when to adopt it, the operator will, of course, be influenced by the relative value of the drug and the menstruum. In order to secure the most favorable results in repercolation, certain methods of proceeding are advisable in various steps of the process, differing with the character of the substance to be acted on; and these can be determined only by a careful study, confirmed by repeated experiment. Squibb used repercolation exclusively on the large scale in the manufacture of extracts and fluidextracts, and applied it especially to the preparation of fluidextracts of cinchona; and since his first paper, which was reproduced in the 14th revision of the U. S. Dispensatory, p. 1164, he introduced several improvements, which are intended to make the process useful to the apothecary in his every-day work. See Type Process C.

The plan of N. Spencer Thomas consists in exposing the substance to be acted on to successive expressions, by means of a press, with the menstruum divided into different portions, so that fresh portions of liquid are brought to act on the same solid body in different stages of exhaustion, and then mixing the expressed liquids. The due proportion between the weight of the medicine and the bulk of the ultimate fluidextract is secured by regulating the measure of the last added portion of menstruum, which, in the process as described by Thomas, is the third. Whatever may be the advantages of this method—and it is not without its recommendations—it is liable to the objection of loss of alcohol through exposure during expression. Another method of limiting the quantity of alcohol used has been proposed by S. P. Dutfield, of Detroit. It consists in macerating, for from six to ten days, the medicine to be acted on, previously deprived, by means of a vacuum apparatus, of all the air, and of all readily volatilizable matter contained in its pores, with a certain volume of the menstruum, which is forced through a tube into the vacuum pan by atmospheric pressure, and thus brought into the most intimate contact with all parts of the powder. The process is completed by submitting the mass thus impregnated to hydraulic pressure, and, after allowing the liquid to settle in glass carboys, drawing off the clear liquid into bottles. It is obviously inapplicable to substances whose virtues depend in any considerable degree upon readily volatilizable constituents. Campbell (A. J. P., xlii, 17) proposed a method for doing away with the use of heat, which, however, although in some cases it may do well, cannot be relied upon for the complete exhaustion of all drugs. Sixteen troyounccs of the powder are moistened with four to six fluid-ounces of the menstruum (usually alcohol), and packed in a glass funnel, a piece of sponge having previously been put in the beak of the funnel; the surface of the powder is covered with a disk of paper, and twelve fluidounces of menstruum poured on. When the sponge becomes saturated, the beak of the funnel is corked tightly and the whole set aside for four days, at the end of which time the percolation may be allowed to proceed without further addition of menstruum. J. W. Mill has called attention to the advantage of separating the powder into fine and coarse parts by means of sieves and packing the finer powder at the bottom.

H. Biroth (Pharm., April, 1877) proposes the method which he termed "insuccation" for making non-alcoholic fluidextracts; the advantages claimed for it are simplicity and economy. Colaz prepared fluidextracts from fresh plants by bruising and crushing them, and placing the mass in a dialyzer suspended in 90 per cent. alcohol; when the dialysis is completed, the liquid is evaporated to free it from alcohol, the remaining aqueous liquid retaining the active constituents in the proportions in which they are found in the plant. (Ph. Post, xxix, 271.) Haussmann (A. J. P., 1895, 291), after examining a large number of commercial fluidextracts, recorded his results in tabular form, and considered that there is great variation in the quality, due to deviation from pharmacopoeial processes.

J. U. Lloyd proposes to recover the alcohol which remains absorbed by the residue after percolation, by mixing the wet residues with an equal bulk or less of dry sawdust, and then percolating this with water. (A. J. P., June, 1877.) Wm. M. Thomson, of Philadelphia, devised a very complete method of preparing fluidextracts on a large scale; the principles of his process are maceration and percolation in vacua, and although the principles which have been applied have long been known, and similar apparatus used by Duffield and others, there are many useful practical points which merit a notice in detail. The percolators are egg-shaped, and made of tinned copper; they are capable of being tightly covered, and communicate by means of stopcocks above and below, and iron and stout rubber tubing, with a very efficient double acting air pump. The moistened powder is packed tightly in the percolator, and the cover securely bolted on. The stopcock in the cover is now opened, which communicates with the air pump and a partial vacuum created in the space above the moistened drug; the stopcock is now closed and another stopcock in the cover opened, which communicates by a tube with the reservoir containing the menstruum. The menstruum, of course, quickly penetrates the powder, taking the place of the interstitial air, and when the powder is saturated it is permitted to macerate in vacuo a sufficient length of time. To start percolation, a receiver is connected with the beak of the percolator, and, the air being exhausted from it, the percolate at once makes its appearance. When the flow slackens, air may be forced by the pump in the space above the powder, if desired, and the receiver again exhausted below. In this way, it can be seen, entire control of these powerful physical forces may be secured. The advantages are very apparent in preventing the loss of volatile principles and alcohol, while protecting from chemical change caused by exposure to the air. It is quite possible to make official fluidextracts without recourse to subsequent evaporation of weak percolate. For a cut of this apparatus, see A. J. P., 1882.

Assaying Fluidextracts.—The number of assay processes for fluidextracts was materially increased in the U. S. P. (9th Rev.) for preparations made from alkaloidal drugs. The process in each case differs but slightly from the process used for the corresponding drug; they will be found in the succeeding pages under their appropriate headings.

A new method of assay for alkaloidal fluid-extracts, especially adapted to the mydriatic leaf drugs in that the interfering chlorophyll is removed, making only one shaking out operation necessary, was proposed by LaWall (J. A. Ph. A., 1912, 29), as follows: Place 25 Gm. of sodium chloride in a 100 mil graduated cylinder, with water sufficient to make 85 mils. Agitate well for 1 minute, then pour upon a dry filter and collect 50 mils of clear filtrate, which can be shaken out as directed in the final shake out of the ordinary assay process, using the solvent directed for the particular drug which is being assayed. The method does not work with cinchona, guarana or other drugs containing large amounts of alkaloids in the form of cincho-tannates.

Fluidextracts U. S. P. IX.

"The fluidextracts of this Pharmacopoeia, with few exceptions, may be classified according to the menstrua used in the extraction of the drugs and the processes of manufacture employed. Several drugs require special manipulation to obtain satisfactory fluidextracts, and for these appropriate formulas have been devised and are printed in full in the text. The following type processes are described, and in each formula the process to be used is designated by reference to the type process:

"Type Process A—In this class are included those fluidextracts that are made with a menstruum of alcohol or a mixture of alcohol and water by the usual process of percolation. Moisten one thousand grammes [or 35 ounces av., 120 grains] of the powdered drug directed with a sufficient quantity of the prescribed menstruum to render it evenly and distinctly damp and to maintain it so, after macerating for six hours in a tightly-covered container. Then pack it in a cylindrical percolator and add enough of the menstruum to saturate the powder and leave a stratum above it. When the liquid begins to drop from the percolator, close the lower orifice, and, having closely covered the percolator, macerate for forty-eight hours. Then allow the percolation to proceed slowly, gradually adding more menstruum until the drug is exhausted. Reserve the first eight hundred and fifty mils [or 28 fluidounces, 356 minims] of the percolate (unless otherwise specified in the formula); recover the alcohol from the remainder and concentrate the residue to a soft extract at a temperature not exceeding 60° C. (140° F.); dissolve this in the reserved portion, mix thoroughly, and finally add a sufficient quantity of the menstruum to obtain one thousand mils [or 33 fluidounces, 6 ½ fluidrachms] or the volume determined by calculation from the assay.

"Type Process B—In this class are included those fluidextracts in which glycerin or an acid is used in the extraction and two menstrua are successively employed. Menstruum I contains the glycerin or acid in definite proportion to the amount of the drug, and Menstruum II, a mixture of alcohol and water intended for completing the exhaustion of the drug. Moisten one 'thousand grammes [or 35 ounces av. 120 grains] of the powdered drug directed with a sufficient quantity of the prescribed Menstruum I, to render it evenly and distinctly damp and to maintain it so after macerating for six hours in a tightly-covered container. Then pack it in a cylindrical percolator, add the remainder of Menstruum I, and, when this has just disappeared from the surface, gradually add Menstruum II, constantly maintaining a stratum of liquid above the drug. When the liquid begins to drop from the percolator, close the lower orifice, and, having closely covered the percolator, macerate for forty-eight hours, and then allow the percolation to proceed slowly, gradually adding Menstruum II until the drug is exhausted. Reserve the first eight 'hundred and fifty mils [or 28 fluidounces, 356 minims] of the percolate (unless otherwise specified in the formula); recover the alcohol from the remainder and concentrate the residue to a soft extract at a temperature not exceeding 60° C. (140° F.); dissolve this in the reserved portion, mix thoroughly, and finally add a sufficient quantity of Menstruum II to obtain one thousand mils [or 33 fluidounces, 6 ½ fluidrachms] or the volume determined by calculation from the assay.

"Type Process C—The process of fractional or divided percolation. This is especially recommended for drugs containing volatile ingredients or constituents injured by exposure to heat. This process may likewise be used as an alternative process in the formulas in which Type Process A is directed. Divide one thousand, grammes [or 35 ounces av., 120 grains] of the powdered drug directed into three portions of five hundred grammes [or 17 ounces av. 279 grains] three hundred grammes [or 10 ounces av. 255 grains] and two hundred grammes [or 7 ounces av. 24 grains] respectively. Moisten the first portion of the drug (500 Gm.) [or 17 ounces av., 279 grains] with a sufficient quantity of the prescribed menstruum to render it evenly and distinctly damp and to maintain it so after macerating for six hours in a tightly-covered container. Then pack it in a cylindrical percolator and add enough of the menstruum to saturate the powder and leave a stratum above it. When the liquid begins to drop from the percolator, close the lower orifice, and, having closely covered the percolator, macerate for forty-eight hours and then allow the percolation to proceed slowly, gradually adding more of the menstruum. Reserve the first two hundred mils [or 6 fluidounces, 366 minims] of percolate and continue the process until the additional percolate measures fifteen hundred mils [or 50 fluidounces, 345 minims], the latter being collected in successive portions of three hundred mils [or 10 fluidounces, 69 minims] each.

"Moisten the second portion of the powdered drug (300 Gm.) [or 10 ounces av. 255 grains] with a sufficient quantity of the percolate collected in the preceding operation immediately after the reserved portion, to render it evenly and distinctly damp and to maintain it so after macerating for six hours in a tightly-covered container. Then pack it in a cylindrical percolator and macerate and percolate as directed for the first part of the drug, using as menstruum the several portions of percolate from the preceding operation in the order in which they have been collected, and, if this be insufficient, follow with some of the original menstruum. Reserve the first three hundred mils [or 10 fluidounces, 69 minims] of percolate and continue the process until the additional percolate measures eight hundred mils [or 27 fluid-ounces, 24 minims] collecting the weaker percolate in successive portions of two hundred mils [or 6 fluidounces, 366 minims] each.

"Moisten the third portion of the powdered drug (200 Gm. [or 7 ounces av. 24 grains]) with a sufficient quantity of the percolate collected in the preceding operation immediately after the reserved portion, to render it evenly and distinctly damp and to maintain it so after macerating for six hours in a tightly-covered container. Then pack it in a cylindrical percolator and macerate and percolate as before, using as menstruum the several portions of percolate from the preceding operation in the order in which they have been collected, and, if this be insufficient, follow with more of the original menstruum. Collect five hundred mils [or 16 fluidounces, 435 minims] of percolate and mix this with the two portions previously reserved so as to make one thousand mils [or 33 fluid-ounce's, 6 ½ fluidrachms] of finished fluidextract.

"When Type Process C is directed for fluidextracts which are adjusted by assay to a definite alkaloidal standard, collect only four hundred and twenty mils [or 14 fluidounces, 97 minims] of percolate from the third portion of drug instead of the five hundred mils [or 16 fluid-ounces, 435 minims] directed above. Mix this percolate with the two portions previously reserved, assay a portion of the mixture and then adjust its volume, by the addition of the menstruum directed, so that each one hundred mils [or 3 fluidounces, 183 minims] of finished fluid-extract will contain the prescribed amount of alkaloid.

"Type Process D—In this class are included those fluidextracts in which extraction is effected by infusion and percolation with boiling water, alcohol being added to the concentrated liquid as a preservative.

To one thousand grammes [or 35 ounces av., 120 grains] of the ground drug add five thousand mils [or 169 fluidounces, 33 minims] of boiling water, mix thoroughly and allow it to macerate in a covered container for two hours in a warm place. Then transfer the moist drug to a tinned or enameled metallic percolator and allow percolation to proceed, gradually adding boiling water until the drug is exhausted. Evaporate the percolate on a water bath or steam bath to the volume specified and when cold add the alcohol directed and mix thoroughly." U. S.

"In the preparation of fluidextracts by either Process A, B, or C, the rate of percolation must be carefully controlled and, for the quantities directed in the formulas of the Pharmacopoeia, the flow should not exceed ten drops per minute until the reserved percolate is collected, and twenty drops per minute thereafter. As a rule one thousand grammes [or 35 ounces av., 120 grains] of powdered drug may be exhausted by percolation with sufficient menstruum to yield three thousand mils [or 101 fluidounces, 212 minims] of percolate.

"Fluidextracts should be kept in tightly-stoppered containers for one month and then, if perfectly clear, they should be stored in amber-colored bottles protected from sunlight and extremes of temperature. If sedimentation has occurred the clear portion should be decanted, the remainder filtered and the liquids thoroughly mixed before storing.

"The percentage of alcohol in fluidextracts made by type processes A, B, or C is variable and always less than that in the menstruum employed, due, among other causes, to loss of alcohol by evaporation during manufacture, to the presence of a variable proportion of water in the air-dried drug, and to the extraction from the drug of its soluble constituents, which also often vary greatly in different lots of the same drug. The percentage of alcohol in the finished product can therefore only be ascertained by an actual determination.